This is not your standard run-of-the-mill pump. This is unique.

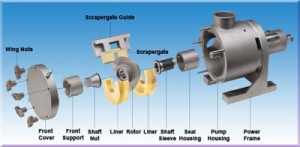

An internal rotating sinusoidal rotor with a scrapergate that goes back and forth to direct the flow is about as simple as the concept gets. But it’s simplicity is deceptive.

If you pull the rotor out and run it across the table, it rolls like a wheel, but it traces a perfect sine curve. The rotor produces two separate chambers that are the opposite sides of the sine curve. The volume flowing in each chamber fluctuates, but those flows go up and down opposite each other, so they add up to a single flow rate.

This pump should be employed mostly in high viscosity applications. It provides very low shear and pulseless flow. It can handle high pressure, high flow, high solids, and high temperature. It is not very good with abrasive materials, as it will wear out quickly.

This pump is used to pump whole boneless chicken breasts, because they fit right into the cavities and move through the pump without being chopped up by a rotor or vanes or an impeller. We also pump extremely thick materials, like 5,000,000 cps silicone (see video).

This pump was developed for the German Dairy industry. It was made to be taken apart easily for cleaning, and is one of the simplest pump designs to maintain. It is often used for pie fillings, because peaches and berries are not turned into jam while going through the pump.

We also pump yogurt with fruit, grease, meat slurries (sausage and hot dog manufacturing, for example), pet food, battery pastes, adhesives, creams and ointments, dough, margarine, pie fillings, filter slurries, sauces, inks, pharmaceutical gels, chocolate, surfactants, and soaps to name a few.

We have trial pumps available and often have to test out the application in order to prove the pump’s abilities. Rumor has it that one trial resulted in the complete collapse of the supply tank, which was not vented. While this is not what you want, it wasn’t a failing of the pump. In fact, this proved the pump has very good suction capabilities. The pump is considered a positive displacement pump, but at low viscosities or extremely high backpressures, the flow will bypass internally. You also have to insure that this pump is primed, as it will not draw with air the way a hose or tubing pump will.

Is every application perfect for a MasoSine pump? No. This is not a pump you would use to replace any application where a centrifugal or other low cost pump is working. This is a pump to solve the problems of other pumps in high viscosity, low shear, high solids, low pulsation applications.

These pumps recently replaced Waukesha lobe pumps at a food plant, pumping a food with large pieces to a filling line. The lobe pump crushed whole potatoes and could not maintain suction on mashed potatoes. We can get a demo pump to a customer quickly to prove out the application prior to buying it. No reason to leap before you look!

Talk to us about your tricky application and maybe we will have a chance to see one in action at your plant.